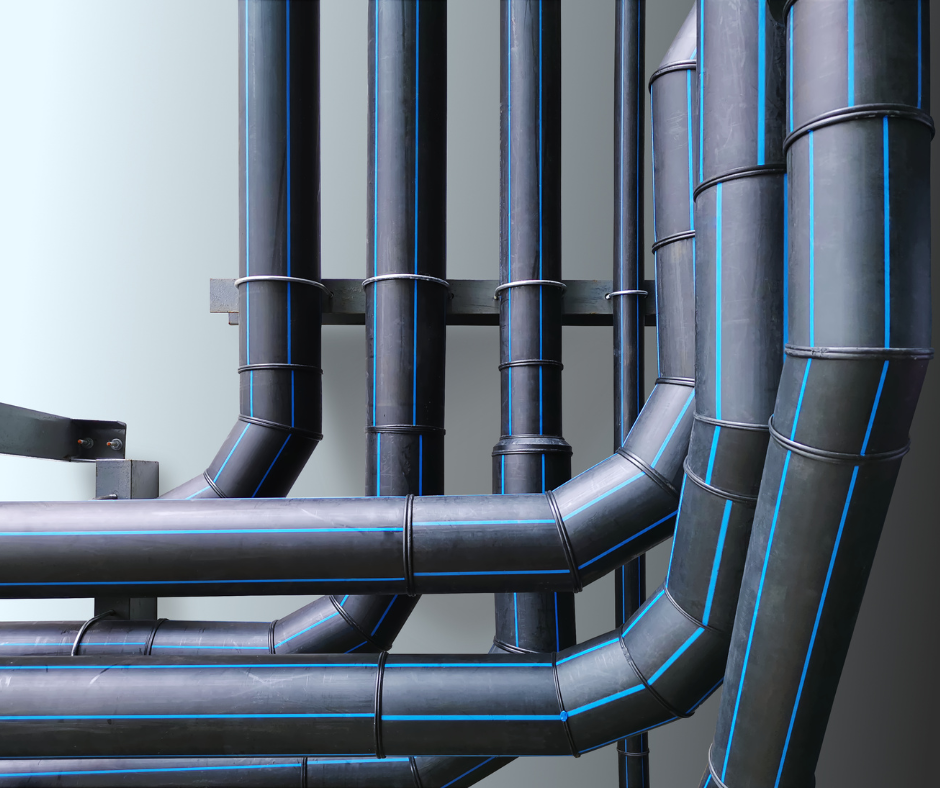

American Plastics LLC Texas: Reliable Pipe Supply for Construction and Renovation Projects

Wiki Article

Discover the Finest Alternatives for Your Following Task With Quality Pipe Products

Picking the ideal pipeline supplies is vital for any type of job. It entails understanding various products and their details applications. High quality plays a critical function in performance and long life. Aspects such as compatibility, schedule, and cost likewise need factor to consider. Making educated choices can considerably influence the outcome of a project. What are the very best choices to explore, and exactly how can one guarantee they are making the right decisions?Comprehending Different Sorts Of Pipeline

When starting on a pipe or construction project, understanding the different kinds of pipelines offered is essential. Different products offer distinct objectives, making it essential to choose the appropriate kind for certain applications. PVC pipes, understood for their lightweight and corrosion-resistant buildings, are frequently used for water drainage and watering. Conversely, copper pipes supply toughness and outstanding thermal conductivity, usually favored for water supply lines. For gas circulation, black iron pipes are a common selection as a result of their strength and resistance to high pressure. Furthermore, PEX (cross-linked polyethylene) pipes have acquired appeal for their versatility and ease of installation, particularly in household plumbing. Each pipeline type has unique attributes that influence its performance and suitability for numerous atmospheres. Familiarity with these choices aids ensure that tasks satisfy safety and security requirements and functional requirements, ultimately adding to the success of any pipes or construction endeavor.Secret Variables to Consider When Picking Pipe Supplies

Choosing the right pipe products needs cautious consideration of several essential variables that can significantly impact the job's result. The certain application of the pipelines have to be examined; different jobs may require differing levels of versatility, sturdiness, and resistance to temperature level or stress. Next, compatibility with existing systems ought to be examined to facilitate smooth combination and protect against future issues.Price is an additional considerable aspect; budget plan constraints may determine the choice of distributors and materials. In addition, the accessibility of products can influence the timeline of the task, making it important to select conveniently available alternatives.

High quality must not be neglected, as inferior materials can cause problems and enhanced upkeep prices. Neighborhood building codes and policies need to be taken into consideration to confirm compliance and security standards. By weighing these aspects, individuals can make informed choices that boost the success of their tasks.

Comparing Materials: PVC, Copper, and PEX

Picking the suitable products for pipeline products is essential for guaranteeing a project's success, and 3 popular choices typically taken into consideration are PVC, copper, and PEX. PVC (polyvinyl chloride) is lightweight, resistant to rust, and economical, making it ideal for numerous applications, particularly in drainage and watering systems (American Plastics LLC). It can be much less durable under severe temperatures.Copper pipes are renowned for their longevity and reliability, using excellent thermal conductivity and resistance to bacteria. Although extra pricey than PVC, their longevity usually justifies the financial investment for plumbing applications.

Applications for Numerous Pipeline Types

Understanding the distinct applications of different pipeline types is necessary for maximizing job end results. PVC pipelines are widely utilized in drainage, waste, and air vent systems because of their resilience and resistance to rust. Their lightweight nature makes them simple to set up and handle. Copper pipelines, known for their reliability and long life, are typically informative post made use of in plumbing and heating unit. Their ability to withstand heats makes them suitable for warm water lines. PEX pipelines, with their adaptability and resistance to freezing, are suitable for household plumbing applications, enabling much easier setup in tight spaces. Additionally, stainless-steel pipelines are frequently employed in commercial setups where high pressure and temperature level resistance are needed. Each pipe type offers details functions, and understanding these applications aids in making notified decisions for different jobs, making sure efficiency and performance.The Value of High Quality in Pipeline Products

Top quality in pipeline products straight influences the success of different tasks, influencing both performance and longevity. High-grade pipelines withstand deterioration, stand up to pressure, and maintain structural integrity in time, making them necessary for making sure safety and security and effectiveness in pipes, construction, and commercial applications. Inferior materials can lead to leakages, failures, and costly fixings, eventually compromising job timelines and spending plans.Moreover, high quality pipelines improve the overall capability of systems, whether they are carrying water, gas, or other materials. They add to perfect circulation rates and lower the risk of contamination, which is specifically important in safe and clean water systems. Purchasing quality pipe provides not only fulfills regulative criteria but additionally supports sustainability by lessening waste through sturdy performance. Therefore, selecting reputable distributors who focus on quality can substantially influence the durability and dependability of any type of job, developing a strong foundation for future operations.

Tips for Maintaining Your Pipelines

Routine upkeep is essential for protecting the integrity and capability of pipelines in any system. To ensure peak efficiency, one reliable technique is to carry out routine examinations, examining for indicators of wear, deterioration, or leakages. Keeping pipelines free and clean from particles can stop obstructions, which frequently cause press build-up and possible tears. It over here is likewise a good idea to keep an eye on water quality, as impurities can damage pipeline products with time.Furthermore, maintaining ideal temperature degrees is necessary; severe changes can create materials to increase or contract, leading to splits. For systems with outdoor piping, protecting pipelines versus cold weather condition can protect against cold and succeeding ruptureds. Documenting upkeep tasks and repair work assists track the problem of the pipelines and aids in future planning. By adhering to these tips, individuals can considerably extend the life expectancy of their piping systems, assuring reliable operation for years ahead.

Where to Locate Reliable Pipe Providers

Maintaining pipes efficiently often begins with sourcing products from reliable suppliers. Trustworthy pipe vendors can be located via numerous networks, including online directory sites, exhibition, and market associations. On-line platforms like Alibaba, ThomasNet, and regional company directories offer comprehensive checklists of suppliers with customer reviews and scores, assisting purchasers evaluate high quality and dependability.Furthermore, going to trade convention permits for straight interaction with providers, allowing job stakeholders to evaluate items firsthand. Networking within market associations can likewise cause valuable recommendations, as specialists frequently share their experiences with various suppliers.

Local hardware stores and plumbing supply shops are exceptional sources, especially for those seeking immediate aid. It's necessary to ask about service warranties and certifications, ensuring that vendors stick to sector criteria. By checking out these avenues, individuals can identify reliable pipeline vendors that satisfy their job's details requirements.

Frequently Asked Questions

What Are the Common Sizes Readily Available for Different Pipe Kinds?

Typical pipe dimensions vary by kind; for instance, PVC pipes usually are available in 1/2", 3/4", and 1" diameters, while steel pipes might range from 1/8" to 36". Selection relies on details application needs.Just how Do I Know if My Pipelines Are Effectively Installed?

To figure out if pipelines are appropriately installed, one must look for safe fittings, appropriate alignment, and absence of leaks - American Plastics Company. Additionally, seeking advice from setup standards and seeking specialist examination can guarantee adherence to safety and security and capability standardsCan I Mix Different Pipe Materials in One System?

Mixing various pipe products in one system is normally not suggested because of possible compatibility problems, such as differing thermal expansion prices and chain reactions. Appropriate installations and adapters may reduce some risks, but care is encouraged.What Safety Precautions Should I Take When Collaborating With Pipes?

When working with pipes, one should use security goggles, gloves, and suitable apparel. Verify proper air flow, usage tools appropriately, handle materials carefully, and comply with producer guidelines to prevent crashes and injuries throughout setup or repair work.Are There Eco-Friendly Pipe Options Available on the marketplace?

Yes, environment-friendly pipeline alternatives are available, including those made from recycled products, naturally degradable plastics, and sustainably sourced timber. These go to this site choices minimize environmental impact while offering sensible solutions for numerous construction and pipes projects.The specific application of the pipes should be analyzed; different tasks may require differing degrees of resistance, adaptability, and durability to temperature or stress. Picking the appropriate products for pipeline materials is crucial for guaranteeing a job's success, and 3 preferred choices typically thought about are PVC, copper, and PEX. Comprehending the distinct applications of various pipeline types is essential for optimizing task outcomes. Quality in pipeline materials straight impacts the success of different tasks, influencing both efficiency and long life. Common pipeline dimensions vary by type; for instance, PVC pipelines generally come in 1/2", 3/4", and 1" sizes, while steel pipelines may range from 1/8" to 36".

Report this wiki page